PCMs in cooling ceilings and heat stores

Flexible use: PCMs in cooling ceilings and heat stores

Phase change materials (PCMs) are of interest for many applications in constructions, as they can be used for cooling, heating, and storing heat. However, to date they have only been used in a limited number of offices and residential buildings. Researchers have studied the reasons for this, and the results are now available.

According to the German Federal Government’s climate protection plan, a virtually climate-neutral building stock should be realized by 2050. Using PCMs can help to unite the cornerstones of energy efficiency and the use of renewable energy sources. If PCM-based heat and cold stores are intelligently integrated into heating and cooling systems, it is possible to ensure a highly efficient supply of heating and cooling. Excess renewable energy can be stored for the short term, allowing for more flexible use. Intelligent grid operation through power-to-heat/cold systems is also possible.

While PCM systems have been the subject of extensive study for decades, achieving great success in the field of research, it has taken much longer for corresponding products to establish themselves on the market. This delay can be attributed to the investment costs, which are still relatively high, and a lack of reference projects for successful PCM installations. To change this, scientists tested different PCM systems in real-world applications and evaluated their operating behaviour. This allowed them to obtain reliable operating data to study the energy performance of the various PCM systems and, in cases where implementation was not successful, to identify possible reasons.

Results

In the project, seven PCM systems were studied at different stages of development and evaluated through monitoring in real-life applications:

- Rear-ventilated PCM cooling ceiling (research installation),

- PCM compact store for ventilation of offices (prototype installation),

- PCM parapet modules for ventilation of offices (research installation),

- Energy storehouse with PCM screed (research installation),

- PCM cooling ceiling with water flow and vertical fins (commercial installation),

- Comfort boards (plasterboard containing PCMs) in walls and ceilings for passive room cooling (commercial installation), comparison of two newly built kindergartens (with and without PCM)

- Modular PCM heat stores for residential buildings (prototype installation)

- The results are now available in a final report (in German).

Cool night air improves efficiency

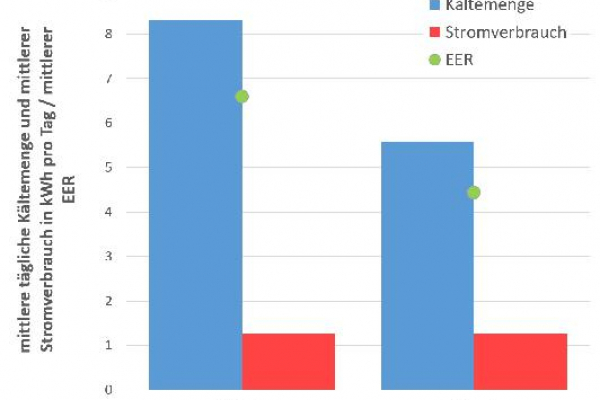

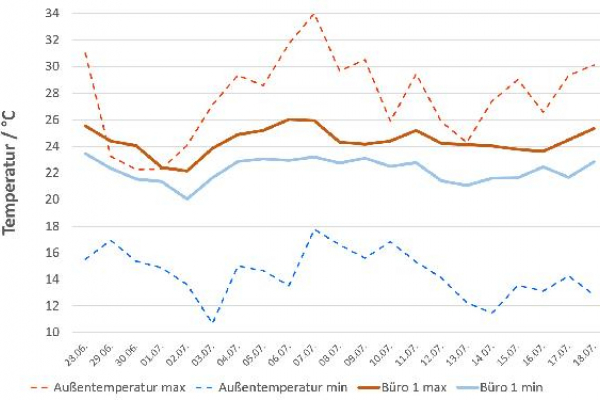

Among the air-driven PCM systems for room cooling, average energy efficiency ratings (EERs) of 4 to 7 (fig. 2) were measured for the ventilation system with PCM compact stores (fig. 1a and b). In this case, the PCMs limited the room air temperatures to a maximum of 26 °C during the summer period that was studied (fig. 3). For the PCM parapet modules, EERs of up to 10 were measured, though these were in some cases at higher room temperatures.

A prerequisite for this high efficiency is that the cool night air used for regenerating the PCMs is always fed into the room after flowing through the PCM store. This allows the residual potential of the still-cool air to be used to cool down the room at night.

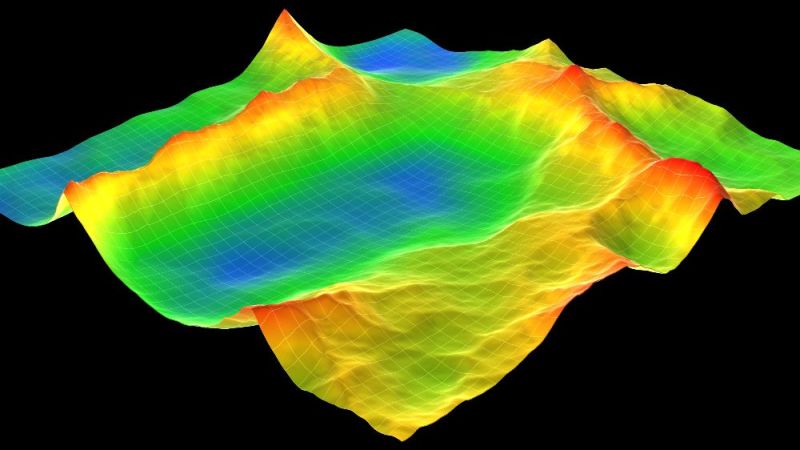

While regeneration of the PCMs in air-driven systems is limited by the temperatures of the outside air, active PCM systems such as the PCM cooling ceilings with water flow studied in the project (fig. 4) are much more flexible to use and allow PCMs with lower melting points and thus greater cooling capacity to be used. Ideally, cooling is passive and performed by the PCMs during the day, while active operation is only used for regeneration at night.

PCM systems for heating buildings can be used in combination with renewable energy sources such as photovoltaics (PV) and heat pumps for power-to-heat application. If PCMs are integrated into building components such as screed (fig. 5), the PCM loading volume must be sufficiently high to enable significant storage effects.

PCM stores for heating buildings allow much greater storage densities than water tanks alone, which reduces the space requirements for these stores. The modular PCM heat stores for residential buildings that were studied in the project (fig. 6) use targeted supercooling of the PCMs to store heat for several days with virtually no heat loss. The project managed to achieve a reliability of 80 % for the supercooled melt.

Putting findings into practice

The project showed that PCM systems can function with extremely high energy efficiency, provided they are realized and operated by qualified experts. It also made clear that PCM systems can be economical under certain conditions.

In order to achieve both aspects, appropriately optimized control strategies must be implemented and the PCM systems must be put into operation in a rational way, ideally with a subsequent monitoring phase. Those involved in the project were able to further develop the industrial partners’ PCM systems in a practical way and implement them as reference systems in the form of pilot projects. Furthermore, they laid the foundation for the development of new, cost-effective PCM encapsulations.

Essential: Information from planners and users

However, it also became clear that in practice PCM systems are not always operated in an optimal manner. Often the control system or the operating parameters are not adjusted for the individual PCM system, even in commercial installations. This can even cause excess energy to be consumed. For example, in training rooms equipped with a PCM cooling ceiling system, the users set the thermostats to temperatures of around 22 °C in almost all cases, which is below the phase change range of the PCMs used. This meant that the PCM system’s passive cooling could not take effect, because the active cooling switched on beforehand. However, the unused PCMs were actively regenerated every night regardless.

These results indicate a substantial need for information and coordination on the part of planners, tradespeople, building operators, and users. This applies in particular to the design, installation, and operation of PCM systems. This coordination is especially difficult with systems that require input from the users to be included. Often the users are not known during the planning and building phases, or might change later. Further research is needed into developing suitable control strategies. The considerable potential for energy savings from PCM systems can only be realized once both of these obstacles have been eliminated.

17.11.2021

Rubitherm Technologies GmbH

http://www.rubitherm.com

info@rubitherm.com

Tel.: +49(30)720004-62

va-Q-tec AG

http://www.va-q-tec.com

info@va-q-tec.com

Tel.: +49(0)931-359420

Universität Kassel, Fachgebiet Bauphysik

http://www.uni-kassel.de/fb6/bpy/

poststelle@uni-kassel.de

Tel.: +49(0)561-804-2779

Fraunhofer-Institut für Solare Energiesysteme ISE

http://www.ise.fraunhofer.de

info@ise.fraunhofer.de

Tel.: +49(0)761-4588-0

Ingenieurbüro Prof. Dr. Hauser GmbH

http://www.ibh-hauser.de

schlitzberger@ibh-hauser.de

Tel.: 0561/9499-0432

Deerns Deutschland GmbH

http://www.deerns.com

henry.geisler@deerns.com

Tel.: 0221 5741 251

H.M. Heizkörper GmbH & Co. KG

http://www.muhr.net

info@muhr.net

Tel.: +49(0)36075-397-0

Ecowin GmbH Prof. Dr. Gäth & Partner

http://www.ecowin.de

alfred.stein@freenet.de